FAQS

CNC Machining FAQs

Injection Molding FAQs

3D printing FAQs

Vacuum Casting FAQs

Sheet Metal Fabrication FAQs

Die Casting FAQs

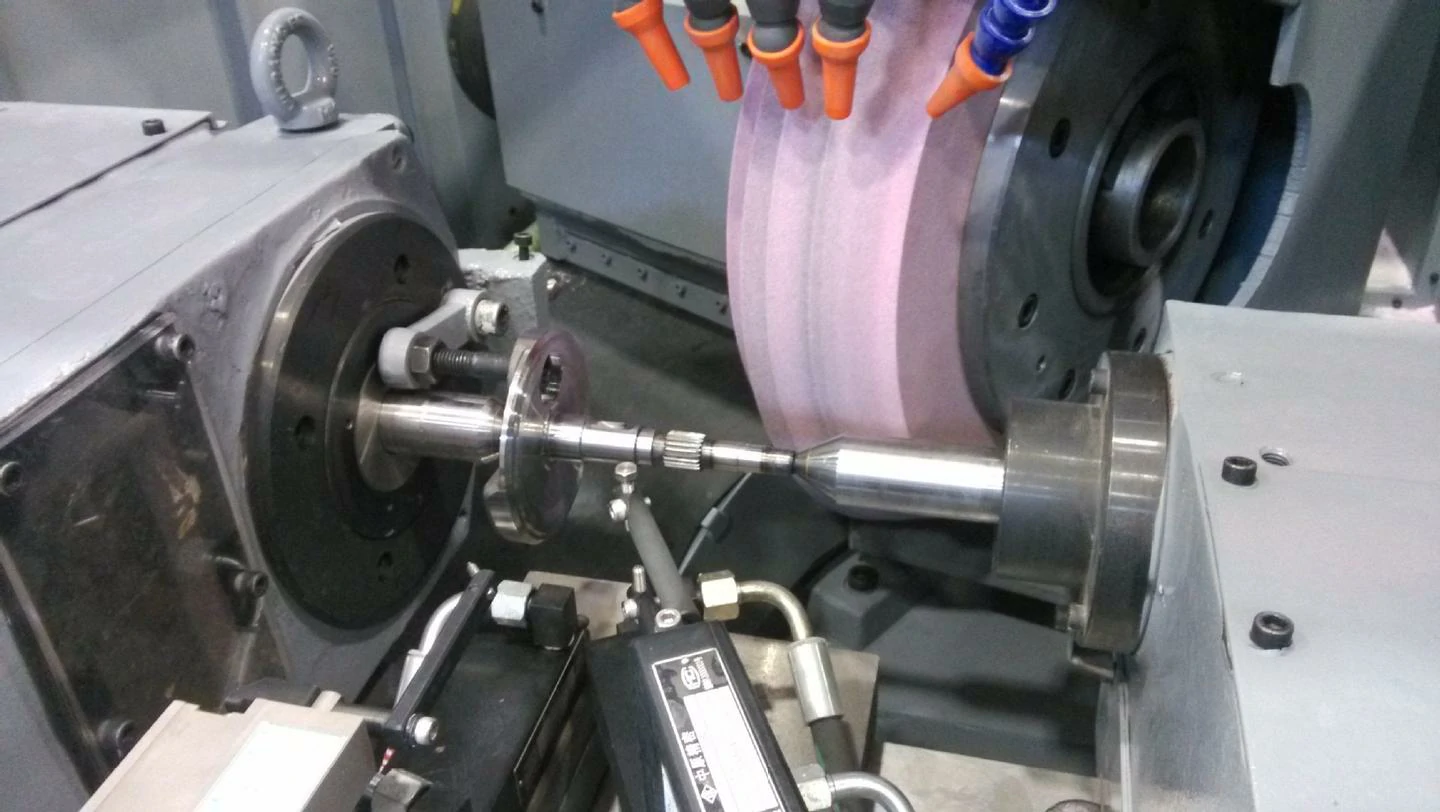

We guarantee that we will follow DIN-2678-1 standards for all CNC machined parts. Parts machined with metal will follow DIN-2678-1-f (fine). Parts machined with plastics will follow DIN-2678-m (medium). Geometric tolerances down to ± 0004 in. (0.01 mm) are possible but must be clearly indicated in technical drawings. We can achieve tighter tolerances on shafts with up to H7 fits with manual quoting and on occasion tighter.

Deburring and edge breaking are standard procedures for all CNC machined parts. If there are any critical edges that should be left sharp, they must be clearly indicated in technical drawings. Surfaces will be free of defects such as scratches, dents, stains, blemishes, hanging marks, minor defects. Surfaces indicated as critical (primary (a) side, as indicated on the technical drawing) will be free of mill steps and other marks. For the secondary (b) side, minor hanging marks and up to 2 minor defects are acceptable. A number of post-processing and finishing methods can be applied to improve the surface roughness, visual properties and wear resistance of machined parts.

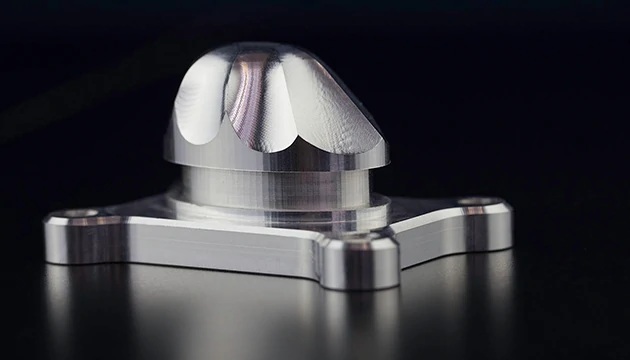

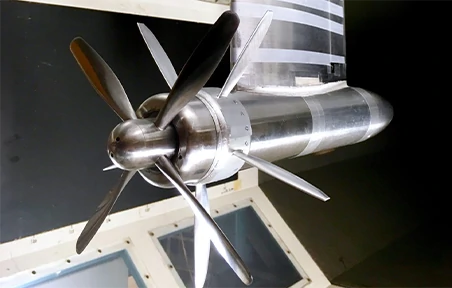

CNC machining is widely used across industries. It is common in aerospace, automotive, consumer electronics, robotics, agriculture, and other fields that frequently use metal parts. It is also widely used in medical devices, household goods, energy, oil and gas, and other consumer applications. It is one of the most common manufacturing processes in the world.

CNC machining uses subtractive processes, which means feedstock is machined to its final form by subtracting and removing material. Holes are drilled, lots and pathways are bored, and metal stock is shaped into new material with varying tapers, diameters, and shapes.

For subtractive manufacturing, shapes are achieved by the subtraction of material. This contrasts with other types such as additive manufacturing — where materials are added, layered, and deformed to a specified shape. It also contrasts with injection molding where the material is injected in a different state of matter, using a mold, and formed to a specified shape. CNC machining is versatile — and can be used with various materials, including metals, plastics, wood, glass, foam, and other composite materials. This versatility has helped make CNC machining a popular choice across industries, enabling designers and engineers to fabricate products efficiently and precisely.

For subtractive manufacturing, shapes are achieved by the subtraction of material. This contrasts with other types such as additive manufacturing — where materials are added, layered, and deformed to a specified shape. It also contrasts with injection molding where the material is injected in a different state of matter, using a mold, and formed to a specified shape. CNC machining is versatile — and can be used with various materials, including metals, plastics, wood, glass, foam, and other composite materials. This versatility has helped make CNC machining a popular choice across industries, enabling designers and engineers to fabricate products efficiently and precisely.

HLH has significant capabilities in machining through our shop services. In general, here are some guidelines for machine size but if you do have a quote that pushes to RFQ please make sure to request a quote review so we can take a look!

5 Axis Machining up to 26″

4 Axis Machining up to 36″

3 Axis Machining up to 60″

Wire EDM with a part depth of 18″

5 Axis Machining up to 26″

4 Axis Machining up to 36″

3 Axis Machining up to 60″

Wire EDM with a part depth of 18″

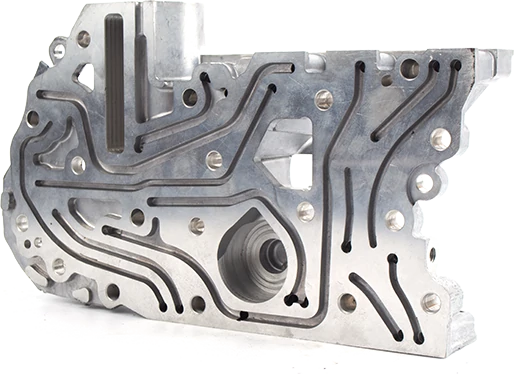

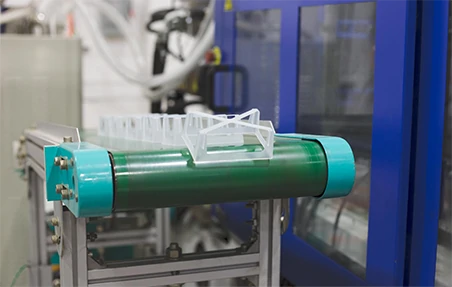

Injection molding is two large metal mold halves coming together, a plastic or rubber material is injected into the cavity they form. Even though the plastic materials being injected are melted, they aren't really heated; the material is pressed into the injection ports (called gates) via a large auger screw. As the material is compressed, it heats and begins to flow into the molds. Once it cools, the two halves separate again and the part pops out. Repeat ten thousand times, and you have a run of injection molded parts ready for use.

A wide variety of industries benefit from the highly versatile process of injection molding, including:

Medical & Pharmaceutical

Eletronics

Construction

Food & Beverage

Automotive

Toys

Agriculture

Consumer Goods

Sporting Goods

Medical & Pharmaceutical

Eletronics

Construction

Food & Beverage

Automotive

Toys

Agriculture

Consumer Goods

Sporting Goods

Injection molding is a fast, cost effective and highly precise manufacturing process used for mass producing complex molded parts in a variety of materials, including thermoplastics, polymers, aluminum, and glass.

How long an injection mold can last depends on several factors: mold material, number of cycles, operating conditions, and time between production runs. The life expectancy of an injection mold can range from 1M+ cycles to less than 500 cycles based on the above criteria.

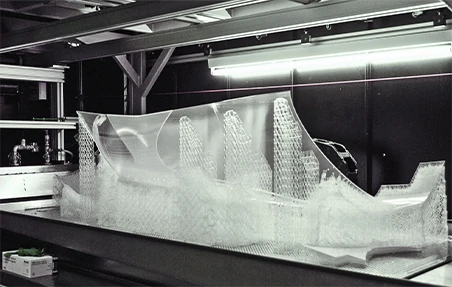

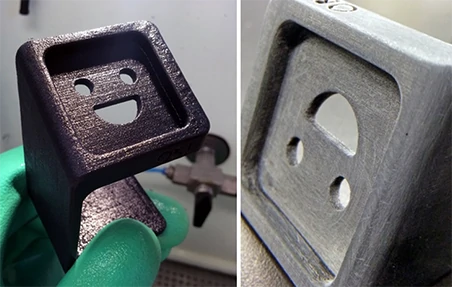

The main costs associated with 3D printing are the number of unique parts, material cost, individual part volume and post-processing requirements. To reduce costs you need to understand the impact of these factors on cost.

The most obvious tip for reducing the cost is to reduce the amount of material used. This can be achieved by reducing the size of your model, hollowing it out, and eliminating the need for support structures.

The second most important tip is to choose the right process for the job. In general, FDM is the most economical 3D printing process for very low volumes (1-10 pieces). SLS, MJF and SLA are more expensive at low volumes, but share similar price ranges and are generally more competitive than FDM for orders of 10 or more pieces. Metal 3D printing is much more expensive than plastic 3D printing.

The third tip is to design parts correctly. Each 3D printing technology has its own benefits and limitations, which affect the affordability of certain design choices.

The most obvious tip for reducing the cost is to reduce the amount of material used. This can be achieved by reducing the size of your model, hollowing it out, and eliminating the need for support structures.

The second most important tip is to choose the right process for the job. In general, FDM is the most economical 3D printing process for very low volumes (1-10 pieces). SLS, MJF and SLA are more expensive at low volumes, but share similar price ranges and are generally more competitive than FDM for orders of 10 or more pieces. Metal 3D printing is much more expensive than plastic 3D printing.

The third tip is to design parts correctly. Each 3D printing technology has its own benefits and limitations, which affect the affordability of certain design choices.

In manufacturing you're only as good as your last order, so we take quality seriously.

Before the goods are sent out, we will have special quality inspectors to check the quality of the goods. We include a comprehensive, standardized inspection report with every order to ensure quality metrics are being met, and offer a first article inspection service on orders of 100+ units.

We also have multiple certifications available on request, including but not limited to ISO9001, ISO14001 and IATF 16949.

Before the goods are sent out, we will have special quality inspectors to check the quality of the goods. We include a comprehensive, standardized inspection report with every order to ensure quality metrics are being met, and offer a first article inspection service on orders of 100+ units.

We also have multiple certifications available on request, including but not limited to ISO9001, ISO14001 and IATF 16949.

There are multiple processes and materials available, which means there are many ways you can approach this problem.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as only a few technologies can produce parts from the same materials.

By use case: once you know whether the part needs to be functional or visually appealing, choosing a process is relatively easy. As a rule of thumb, thermoplastic polymer parts are better suited for functional applications while thermosets are best suited for visual appearance.

The third tip is to design parts correctly. Each 3D printing technology has its own benefits and limitations, which affect the affordability of certain design choices.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as only a few technologies can produce parts from the same materials.

By use case: once you know whether the part needs to be functional or visually appealing, choosing a process is relatively easy. As a rule of thumb, thermoplastic polymer parts are better suited for functional applications while thermosets are best suited for visual appearance.

The third tip is to design parts correctly. Each 3D printing technology has its own benefits and limitations, which affect the affordability of certain design choices.

Vacuum casting is a more affordable alternative to IM, especially in low volumes. It also offers unique advantages like an excellent surface finish.

Vacuum casting is best for making visually impressive prototypes, but it can also be used for non-mechanical end-use parts like cases and covers.

The silicone molds used in vacuum casting have a short lifespan, typically around 20 moldings, so we dispose of them after use.

With vacuum casting, you can get production quality parts at low volumes and without the high costs and lead times of steel or aluminum tooling. This is helpful for bringing new products to market where you may want production-grade products to test with new customers and markets and validate your design hypotheses before making a substantial investment to scale manufacturing.

If you are familiar with designing parts for injection molding, you can apply the same best practices and rules of thumb to design parts for vacuum casting.

Sheet metal fabrication is a manufacturing method that involves cutting and bending sheets of metal to form different shapes.

Sheet metal fabrication is more cost-effective than CNC machining when it comes to metal components with uniform wall thickness.

Sheet metal fabrication is more cost-effective than CNC machining when it comes to metal components with uniform wall thickness.

There are 3 common stages in the sheet metal fabrication process, all of which can be completed with various types of fabrication tools.

- Material Removal

- Material Deformation (forming)

- Assembling.

- Material Removal

- Material Deformation (forming)

- Assembling.

HLH has more than decades of experience in sheet metal processing. Our professional engineers can provide you with free consultation and design solutions. Our quality team can ensure your parts consistently meet your quality expectations. We also offer phone, email and chat support for any concerns or questions you may have.

There are 5 steps to produce die casting products.

Step 1: Prepare mold. You need to heat the mold to a specific temperature and then spray the interiors of the mold with a refractory coating or lubricant.

Step 2: Inject material. After the solid metal alloy is melted into a liquid state, pour molten metal into the mold under a required pressure.

Step 3: Cool the metal. Once the molten metal is injected into the cavity, take sufficient time to let it harden so that it can form the shape of the mold.

Step 4: Unclamp the mold. Next, unclamp the mold carefully and take out the cast part.

Step 5: Trim the casting part. The last step is to trim sharp edges and excess material to make the desired component shape.

Step 1: Prepare mold. You need to heat the mold to a specific temperature and then spray the interiors of the mold with a refractory coating or lubricant.

Step 2: Inject material. After the solid metal alloy is melted into a liquid state, pour molten metal into the mold under a required pressure.

Step 3: Cool the metal. Once the molten metal is injected into the cavity, take sufficient time to let it harden so that it can form the shape of the mold.

Step 4: Unclamp the mold. Next, unclamp the mold carefully and take out the cast part.

Step 5: Trim the casting part. The last step is to trim sharp edges and excess material to make the desired component shape.

There is no fixed answer. The casting parts are commonly produced using aluminum, zinc and magnesium that are not mainly made from iron, which makes them corrosion resistant and hardly rust. But if you don't protect your products in the right way for a long time, there is the possibility that they will rust.

There are numbers of metals and alloys to choose for die casting project. The commonly used metals are zinc, aluminum and magnesium. Also, you can choose copper, brass, tin and lead for custom casting parts, However, it's hard to determine the best metal because each metal alloy has its unique physical characteristics, advantages and disadvantages. Therefore, if choosing the ideal metal bothers you, a custom die casting parts manufacturer HLH can help you.