Surface Finishing Service

Your one-stop shop for manufacturing and surface finishing. Get your metal and plastic parts sandblasted, anodized, or powder coated in as fast as 5 days.

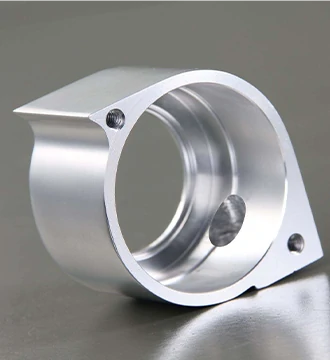

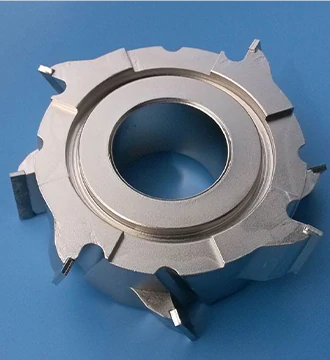

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

Your one-stop shop for manufacturing and surface finishing. Get your metal and plastic parts sandblasted, anodized, or powder coated in as fast as 5 days.

Use HLH as your one-stop solution for both manufacturing and surface finishing of your custom CNC machined parts, reducing the risk of production. Here is a list of standard surface finishes. For custom surface finishes such as laser cutting or hard anodizing, please contact: info@prototypeshlh.com

Polishing

Polishing refers to the use of mechanical, chemical or electrochemical action to reduce the surface roughness of the product to obtain a bright and smooth surface. It is the modification of the surface of the product with polishing tools and abrasive particles or other polishing media.

Applicable Materials: PC, PMMA, Steel, Stainless steel, brass, copper, Aluminum, etc

Texture: Smooth, glossy finish

Surface roughness: Ra 0.2μm / Ra 32μm

Function: Reduce product surface roughness, improve product appearance

Anodizing

Anodizing refers to the electrochemical anodizing of metals or alloys. Under the corresponding electrolyte and specific process conditions, aluminum and its alloys form an oxide film on the aluminum product (anode) due to the action of the applied current.

Applicable Materials: Aluminum

Colors: Any RAL code or Pantone number

Thickness: 5-20μm

Function: Make the products not easy to be scratched, not easy to be corroded

Sandblasting

Sandblasting is the process of cleaning and roughening the surface of the substrate by the impact of high-speed sand flow. Due to the impact and cutting effect of abrasives on the surface of the product, the surface of the product can obtain a certain degree of cleanliness and different roughness.

Applicable Materials: Aluminum, Steel, Stainless Steel, Brass, Copper

Color: Natural color of raw material

Texture: Uniform matte

Function: Improve the mechanical properties and fatigue resistance of the product, and increase the service life of the parts

Painting

Painting refers to the surface coating processing of industrial products. Spray the specified color according to the customer's getImgUrlments.

Applicable Materials: ABS,PC,PMMA,Aluminum,Stainless Steel

Color: Any RAL code or Pantone number

Texture: Uniform gloss or matte

Function: Improve the appearance of the product, and extend the service life of the product through an extra layer of protection.

Powder Coating

This is a coating process that uses corona discharge to make powder coatings adhere to the product. A wide variety of colors are available to create the desired aesthetic.

Applicable Materials: Aluminum, Steel, Stainless Steel

Color: Any RAL code or Pantone number

Thickness: 200-300μm

Function: Improve product appearance. Make products more wear-resistant and corrosion-resistant

Passivation

Passivation refers to the process in which the metal is oxidized by a strong oxidant or electrochemical method to make the surface into an inactive state.

Applicable Materials: Steel, Stainless Steel

Color: Natural color of raw material

Texture: Smooth glossy finish

Function: Make products more corrosion-resistant. Increase the service life of the parts

Zinc Plating

This process is done by coating the part in a flux and dipping the part into molten zinc. The molten zinc forms a bond with the steel, creating a protective layer on the surface of the part.

Applicable Materials: Steel, Stainless Steel

Texture: Smooth finish

Can be applied with: Sandblasting, Passivation

Function: Prevent product surface oxidation or corrosion

Nickel Plating

Nickel plating is a process used to electroplate a thin layer of nickel onto a metal part.

Applicable Materials: Aluminum, Steel, Stainless Steel

Texture: Smooth finish

Can be applied with: Sandblasting, Painting

Function: Make the product resistant to corrosion and abrasion, as well as for decorative purposes

Electropolishing

Electropolishing is an electrochemical process used to clean metallic surfaces and reduce micro-roughness of stainless steel parts. Useful to remove a thin (up to 10μm) layer of material.

Applicable Materials: Steel, Stainless Steel

Texture: Smooth, glossy finish

Color: Natural color of raw material

Function: Improve surface finish