12,000 sq/m Manufacturing Facility

Experienced Engineers

Up-to-date Machines

Satisfied customers

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

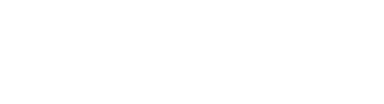

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

Direct metal laser sintering (DMLS) is a metal 3D printing technology used to build metal parts with exceptional mechanical properties and precision.

12,000 sq/m Manufacturing Facility

Experienced Engineers

Up-to-date Machines

Satisfied customers

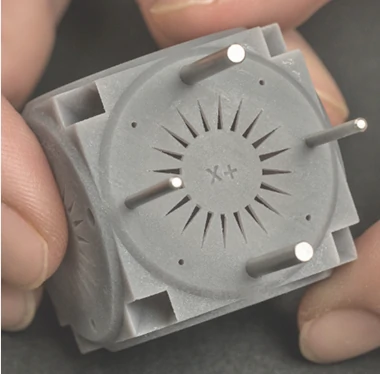

Direct metal laser sintering (DMLS) is an additive metal printing technology that builds metal parts from a CAD file by selectively fusing stainless steel or aluminum powder into thin layers. Direct metal laser sintering’s layer-by-layer printing allows multiple parts to be combined during the printing process.

Direct Metal Laser Sintering or DMLS is an industrial 3D printing technology which builds parts from a range of metal materials one layer at a time by sintering metal powders together. This process is capable of building highly complex shapes which would be near impossible to make via other methods.

Maximum Build Size:

750 × 750 × 750 mm

Standard Lead Time:

6 business days

Dimensional Accuracy:

± 0.5% with a Lower limit of ± 0.15 mm (± 0.006")

Layer Height:

25-100 um

Aluminum AlSi10Mg

Stainless Steel 17-4

Stainless Steel 316/L

Nickel base superalloy

Surface finishes can serve either a functional or aesthetic purpose. Surface finishes that serve both purposes are deemed cosmetic finishes, and are used for cosmetic parts. Producing cosmetic parts requires additional measures to minimize defects such as hang marks and scratches from tools.

√ Deburr

√ Painting

√ Plate

Request a quote

Securely upload your part designs to our platform

Confirm specifications

Configure your part specifications and choose a delivery time that fits your schedule

Production

We select the best manufacturer for your order and start production immediately

QC

We take full responsibility for ensuring your parts are manufactured to our standards

Deliver goods

We handle all order logistics and communications, making sure your parts arrive on time.