- info@prototypeshlh.com

- +86-133-9285-9203

- Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

SERVICES

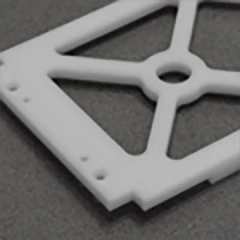

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

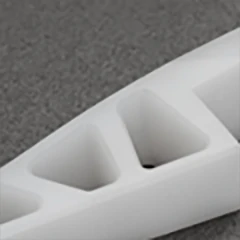

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

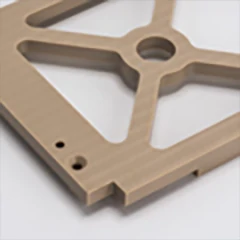

A wide range of materials for CNC machining, with applications in A wide range of materials for CNC machining, with applications in multiple industries. Ideal for both one off prototypes and end-use custom parts.

POM (Delrin/Acetal)

High stiffness, high accuracy, low friction, easy to machine.

Nylon

Excellent mechanical properties, thermal, chemical and abrasion resistant.

ABS

Common thermoplastic, impact resistant, easy to machine.

PEEK

High-performance thermoplastic, very high strength, thermal and chemical resistant.

PTFE (Teflon)

Low friction, chemical and thermal resistant.

Polycarbonate

High toughness, excellent impact strength, transparent.

Polyethylene

Excellent strength-to-weight ratio, impact and weather resistant.

PVC

Excellent chemical and weather resistance and good toughness.

PMMA (Acrylic)

Transparent rigid plastic often used as a substitute for glass.

PET

Tough plastic that offers excellent wear resistance and mechanical strength.

Polypropylene

Excellent chemical resistance. Food-safe grades available.

G-10

High strength, low moisture absorption, and high level of electrical insulation and chemical resistance.

FR4

Flame retardant glass fiber epoxy laminate.

Aluminum

High machinability and ductility, goodstrength-to-weight ratio.

Stainless steel

High tensile strength, corrosion and temperature resistant.

Mild steel

High machinability and weldability, high stiffness.

Brass

Low friction, excellent electrical conductivity, golden appearance.

Copper

Excellent thermal and electrical conductivity

Alloy steel

High strength and toughness, fatigue resistant.

Tool steel

High hardness and stiffness, abrasion resistant.

Titanium

Excellent strength to weight ratio, used in aerospace, automotive and medical industries.

Inconel

High-strength and corrosion-resistant nickel alloy.

Invar

High-strength and corrosion-resistant nickel alloy.