2.Issue:

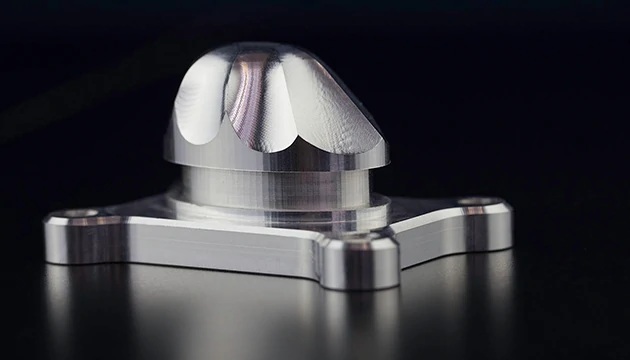

Although this was an internal part, perfection was called for to reduce noise (created by airflow) as much as possible. No flash and no interior surface imperfections would achieve the desired end result.

There is a lot of testing required on many Automotive parts, and timelines are tight. That is where our experience in rapid prototyping comes in.

Rapid prototype work requires excellent quality the first time around. If we lacked in quality, we would not last long in the rapid prototyping world.

It is that attention to detail and quality in rapid prototyping that helps us win projects when it comes to rapid low-volume injection molding. Deliver parts fast and deliver excellence.

Service:Rapid Tooling and Low-Volume Injection Molding

Quantity: 1 Tool - 50 Parts

Material Tooling: ABS + PEEK + PA .

Finishing:P20 Material Parts: PP

Lead Time:21 Days

This injection moulding project was about paying extra attention to the fabrication processes and quality control. Not all interior parts need to be perfect because many are never seen. This part was never seen but perfection was required for desired functionality.