- info@prototypeshlh.com

- +86-133-9285-9203

- Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

SERVICES

CNC Machining Service

Tight tolerances and finishing capabilities, as fast as 2 days.

Vacuum Casting Service

Production quality parts without the tooling investment.

Sheet Metal Fabrication

Experience the versatility 6 cost efficiency withflexible application options.

Die Casting Service

Create high quality custom mechanicals withprecision and accuracy.

Injection Molding Service

Production-grade steel tooling, as fast as weeks.

Carbon Fiber Manufacturing

Composite materials, such as carbon fiber reinforced plastics are highly versatile and efficiert materials.

Popular Services

Injection Molding Service

A faster, easier way to order high-quality injection molded parts that accelerates iteration, testing, and scaled production. Upload your designs for DFM feedback and pricing in 24 hours.

3D Printing Service

Our 3D printing solutions cater to personalised needs with a diverse range of materials and colour options, including SLA, SLS, FDM, Projet, DMLS, and MJF printing services.

Surface Finishing

The easiest way to source your custom parts, with 15+ surface finishing options.

Design Guide

In-depth design guides full of best practices for all of HLH's manufacturing processes.

Case Studies

Success stories from innovativecompanies using HLH.

Blog

lndustry trends, company news andproduct updates.

Featured Posts

Aerospace & UAV

HLH is your 3D manufacturing partner from prototype to large scale production.

Consumer Products

New Product Introduction Solutions for Consumer Products.

Automotive

New Product Introduction Solutions for Automotive.

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Communications

We understand the demands and ever changing landscape of the communications industry.

Product Development

Industrial design and engineering consultancies are some of the most innovate and creative enterprises on the planet.

Projection 3D printing, often associated with Digital Light Processing (DLP) and other resin-based technologies, utilizes a digital light projector to selectively cure liquid resin layer by layer. This method is distinct from conventional 3D printing technologies like Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) because it allows for rapid production of highly detailed and smooth-finish parts.

As industries continue to evolve, projection 3D printing is emerging as a game-changer in the realm of mass production. This innovative technology offers unique benefits that set it apart from traditional manufacturing methods, making it an attractive option for companies looking to scale their production processes. Here, we explore the key advantages of projection 3D printing for mass production.

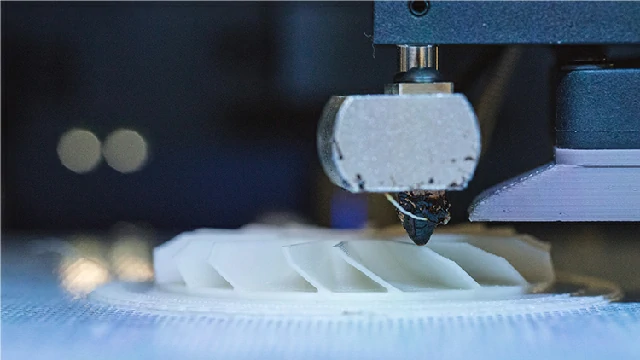

(FDM 3D printing)

One of the standout features of projection 3D printing is its remarkable speed. This method utilizes light to cure resin, allowing multiple layers to be created simultaneously. Compared to conventional 3D printing techniques, projection 3D printing significantly reduces production times, enabling companies to manufacture large quantities of parts quickly. This efficiency is especially beneficial for industries that demand rapid turnaround times, such as automotive and consumer goods.

Projection 3D printing is known for its ability to produce highly detailed and precise components. This level of accuracy is essential in applications where intricate designs are required. With the capability to create complex geometries and fine details, projection 3D printing ensures that the final products meet the exact specifications needed for functionality and aesthetics.

While initial investments in 3D printing technology can be significant, projection 3D printing can be cost-effective for mass production in the long run. By reducing material waste and decreasing production times, businesses can lower their overall manufacturing costs. Additionally, the ability to produce multiple parts in a single build reduces the need for extensive tooling and setup, further enhancing cost efficiency.

Projection 3D printing supports a wide variety of materials, from standard resins to advanced composites. This versatility allows manufacturers to choose materials that best fit their product requirements, whether that’s strength, flexibility, or heat resistance. With ongoing advancements in material science, the range of available options continues to expand, opening new possibilities for product development.

In today's market, customization is becoming increasingly important. Projection 3D printing allows for easy modifications to designs, enabling manufacturers to produce personalized or tailored products without significant changes to the production process. This flexibility is invaluable in industries such as healthcare, where customized implants or devices are often required.

With traditional manufacturing methods, lead times can be prolonged due to tooling setup and production scheduling. Projection 3D printing streamlines this process, allowing for quicker project initiation and faster delivery of products to market. By reducing lead times, companies can respond more rapidly to market demands and stay competitive.

Unlike traditional methods that require molds or dies, projection 3D printing doesn’t require additional tooling, reducing both time and cost, and enabling more complex geometries to be produced.

Projection 3D printing is highly scalable, allowing for easy adaptation from small batch production to larger, high-volume manufacturing, ensuring a smooth transition as demand grows.

Projection 3D printing is widely used across industries for large-scale production, including:

•Medical Industry: Custom prosthetics, dental implants, and biocompatible devices.

•Automotive: Rapid production of lightweight, durable components.

•Consumer Goods: High-detail prototypes and end-use parts such as wearables and electronics.

•Aerospace: Production of lightweight structural components with intricate designs.

(HLH 3D Printing Room)

Projection 3D printing offers a compelling solution for mass production, particularly when you need high precision, complex designs, and low-volume or medium-volume production. It enables faster lead times, lower tooling costs, and higher levels of customization compared to traditional methods, while also providing flexibility, material variety, and the ability to manufacture end-use parts.

As the technology continues to mature, projection 3D printing is poised to revolutionize industries by offering more efficient, cost-effective, and sustainable alternatives to traditional manufacturing processes.

For more information or to explore how projection 3D printing can benefit your production needs, contact us today!